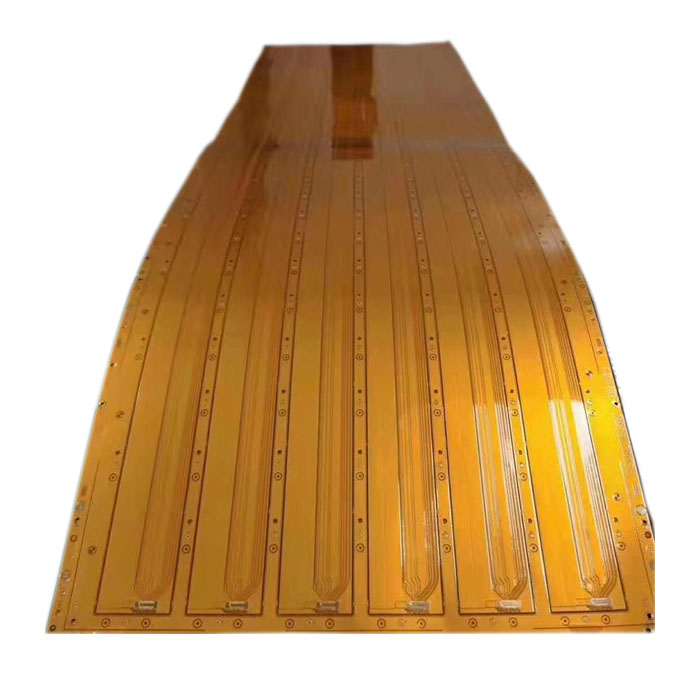

- 1.4M lenght 2 layer Flexible board

- 【Brief】:

Item Specification 1 Numbr of Layer 2Layers 2 Material Polymide 1000mm 3 Surface Finish ENIG 4 Finish Board Thickness 0.2mm 5 Copper Thickness 1/2 oz 6 Solder Mask Yellow 7 Min.Trace Width & Line Spacing 0.075mm/0.1mm(3mil/4mil) 8 Min.Hole Diameter for CNC Driling 0.1mm(4mil) 9 Min.Hole Diameter for punching 0.9mm(35mil) 10 Biggest panel size 610mm*508mm 11 Hole Positon +/-0.075mm(3mil) CNC Driling 12 Conductor Width(W) 0.05mm(2mil)or;

+/-20% of original artwork

13 Hole Diameter(H) PTH L:+/-0.075mm(3mil);

Non-PTH L:+/-0.05mm(2mil)

14 Outline Tolerance 0.125mm(5mil) CNC Routing;

+/-0.15mm(6mil) by Punching

15 Warp & Twist 0.70% 16 Insulation Resistance 10Kohm-20Mohm 17 Conductivity <50ohm 18 Test Voltage 10-300V 19 Panel Size 110×100mm(min);660×600mm(max) 20 Layer-layer misregistration 4 layers:0.15mm(6mil)max;

6 layers:0.25mm(10mil)max

21 Min.spacing between hole edge to circuity pqttern of an inner layer 0.25mm(10mil) 22 Min.spacing between board oulineto circuitry pattern of an inner layer 0.25mm(10mil) 23 Board thickness tolerance 4 layers:+/-0.13mm(5mil);

6 layers:+/-0.15mm(6mil)

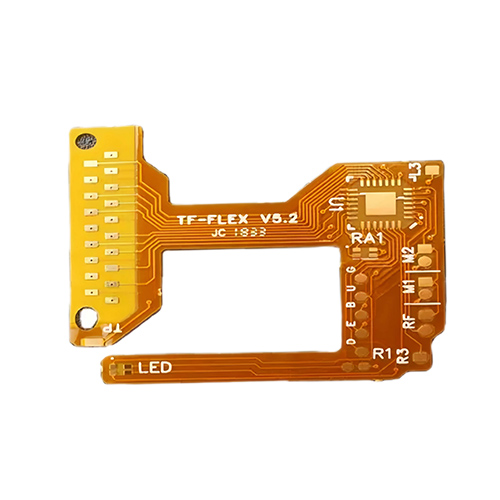

24 Impedance Control +/-10% 25 Different Impendance +-/10% - 【Series】:Flexible PCB

1.China FPC Manufacture Flex Board Flexible PCB Supplier

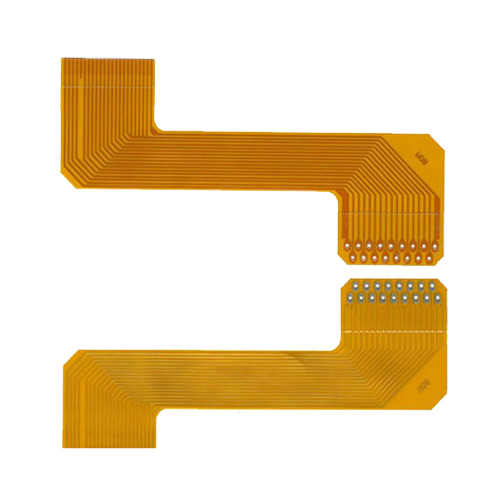

2.Introduction of Flexible PCB Cable PCB

This is a type of polyimide PCB for the application of cable. It’s a single sided layer board at 0.1mm thick.

The base laminate is from ITEQ, Solder mask and silkscreen from Taiyo. It’s fabricated per IPC 6012 Class 2 using supplied Gerber data.

LDES Circuits is capable of providing full turnkey and partial turnkey printed circuit board assembly services.

For full turnkey, we take care of the entire process, including preparation of Printed Circuit Boards,

procurement of components, online order tracking, continuous monitoring of quality and final assembly.

Whereas for partial turnkey, the customer can provide the PCBs and certain components, and the remaining parts will be handled by us.

3.Features-Our Products Advantage

1. Over 10 years experience manufacturer in PCB Assemble and PCB field.

2. Big scale of producing makes sure that your purchase cost is lower.

3. Advanced production line guarantees stable quality and long life span.

4. Produce almost any PCB as your requirement.

5. 100% test for all customized PCB products.

6. One-stop Service ,we can help to purchase the components.

4.Standard Flex Materials:

Polyimide (Kapton) 0.5 mil to 5 mils (.012mm - .127mm)

Adhesiveless Copper Clad Base Material 1 mil to 5 mils

Flame Retardant Laminate, Base Material, and Coverlay

High Performance Epoxy Laminate and Prepreg

High Performance Polyimide Laminate and Prepreg

UL and RoHS Compliant Material on request

High Tg FR4 (170+ Tg), Polyimide (260+ Tg)

Base Copper:

1/3 oz. - .00047 in. (.012mm)–rarely used

1/2 oz. - .0007 in. (.018mm)

1 oz. - .0014 in. (.036mm)

2 oz. - .0028 in. (.071mm)

Solder Mask: Customized

Polyimide Coverlay: 0.5 mil to 5 mils Kapton (.012mm - .127mm)

with 0.5 to 2 mil Adhesive (.012mm - .051mm)

LPI and LDI Flexible Soldermasks

5.Flex PCB Capability

| LDES Circuits Co., Limited | |

| FPC Technology and Capabilities | |

| Material | FR4, Polyimide / Polyester |

| Counts | Flex: 1~8L; Rigid-Flex: 2~8L |

| Board Thickness | Min.0.05mm; Max. 0.3mm |

| Copper Thickness | 1/3 oz — 2 oz |

| CNC Drill Size (Max) | 6.5mm |

| CNC Drill Size (Min) | Flex: 0.15mm |

| Holes Location Tolerance | ±0.05mm |

| Coverlay Drill Size (Min) | 0.6mm |

| Hole to Coverlay Opening Windows (Min) | 0.15mm |

| Min Line Width / Spacing | 0.1/0.1mm |

| Copper Thickness on Hole Wall | Flex:12-22μm |

| Min Pad Size | φ0.2mm |

| Etch Tolerance | Finished line width tolerance ±20% |

| Pattern Registration Tolerance | ±0.1mm (Working Panel Size: 250*300mm) |

| Coverlay Registration Tolerance | ±0.15mm |

| Solder Mask Registration Tolerance | ±0.2mm |

| Solder Mask to PAD | Non photosensitive: 0.2mm |

|

|

Photosensitive: 0.1mm |

| Min. Solder Mask Dam | 0.1mm |

| Misregistration Tolerance | ±0.30mm |

| for Stiffener, Adhesive, Glue paper |

|

| Surface Finish | Plating Ni / Au ; Chemical Ni / Au ; OSP |

6.Workshop