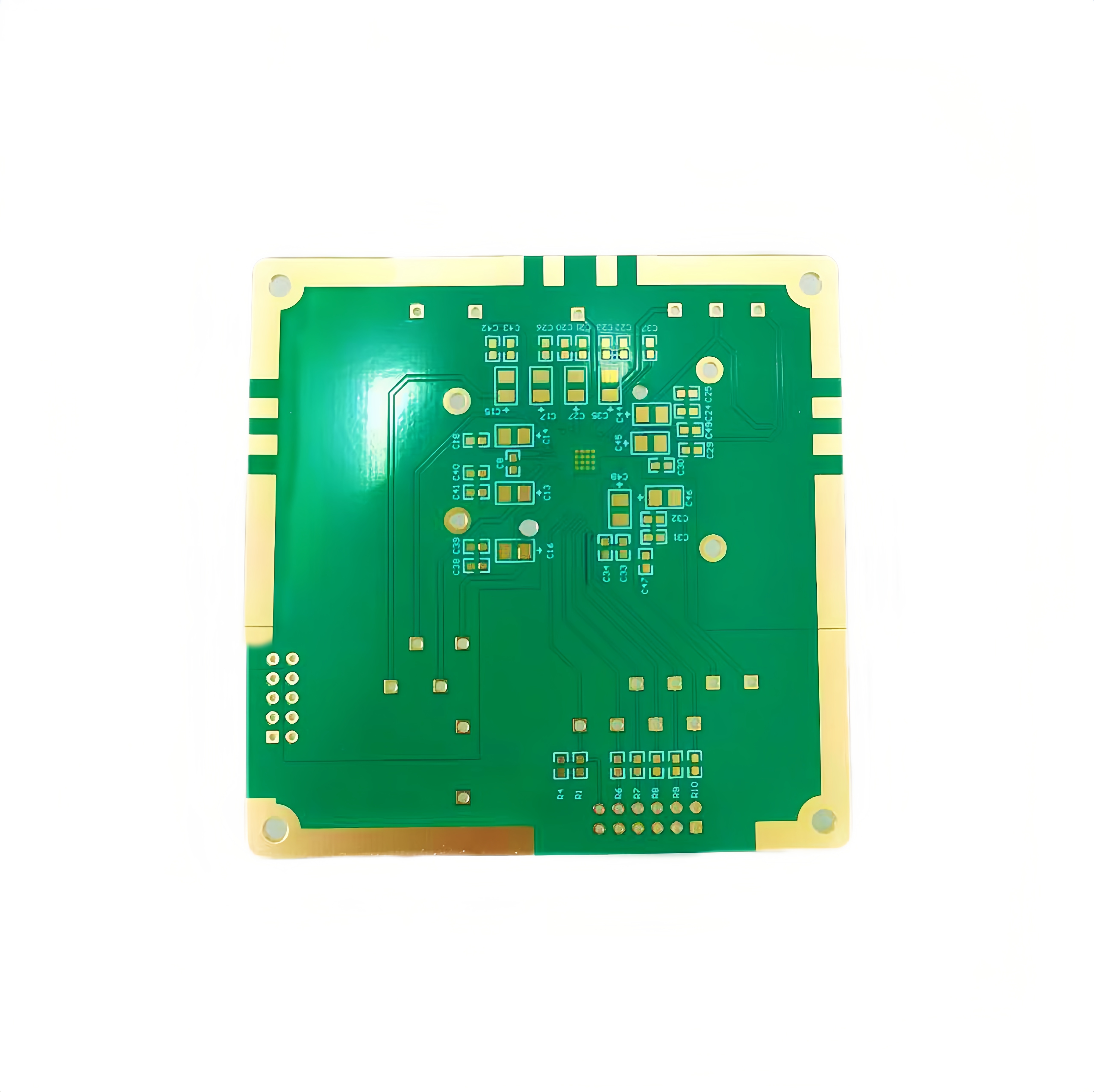

- 6 Layer PCB(Blind and Bruied holes)

- 【Brief】:

Model Number: 6 Layer PCB (Blind and Bruied holes)

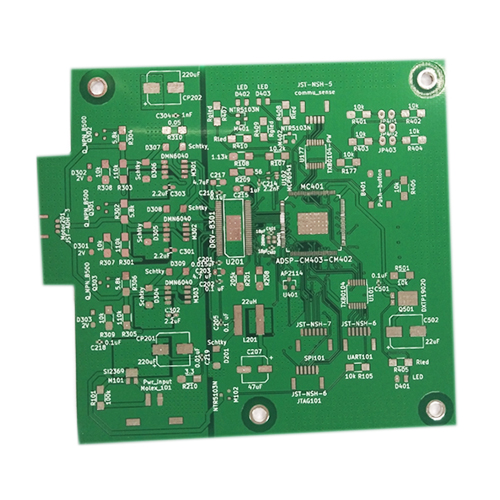

Place of Origin:Guangdong, China

Brand Name: LDSPCB

Base Material: FR-4

Copper Thickness: 1-2oz

Board Thickness: 1.6mm

Min. Hole Size: 0.10mm

Min. Line Width: 0.076mm/3mil

Min. Line Spacing: 0.076mm/3mil

Surface Finishing: ENIG

Impedance control: 90 /100±10% ohm

- 【Series】:FR4 PCB

1.Capability:

| layer | 1-50 layer |

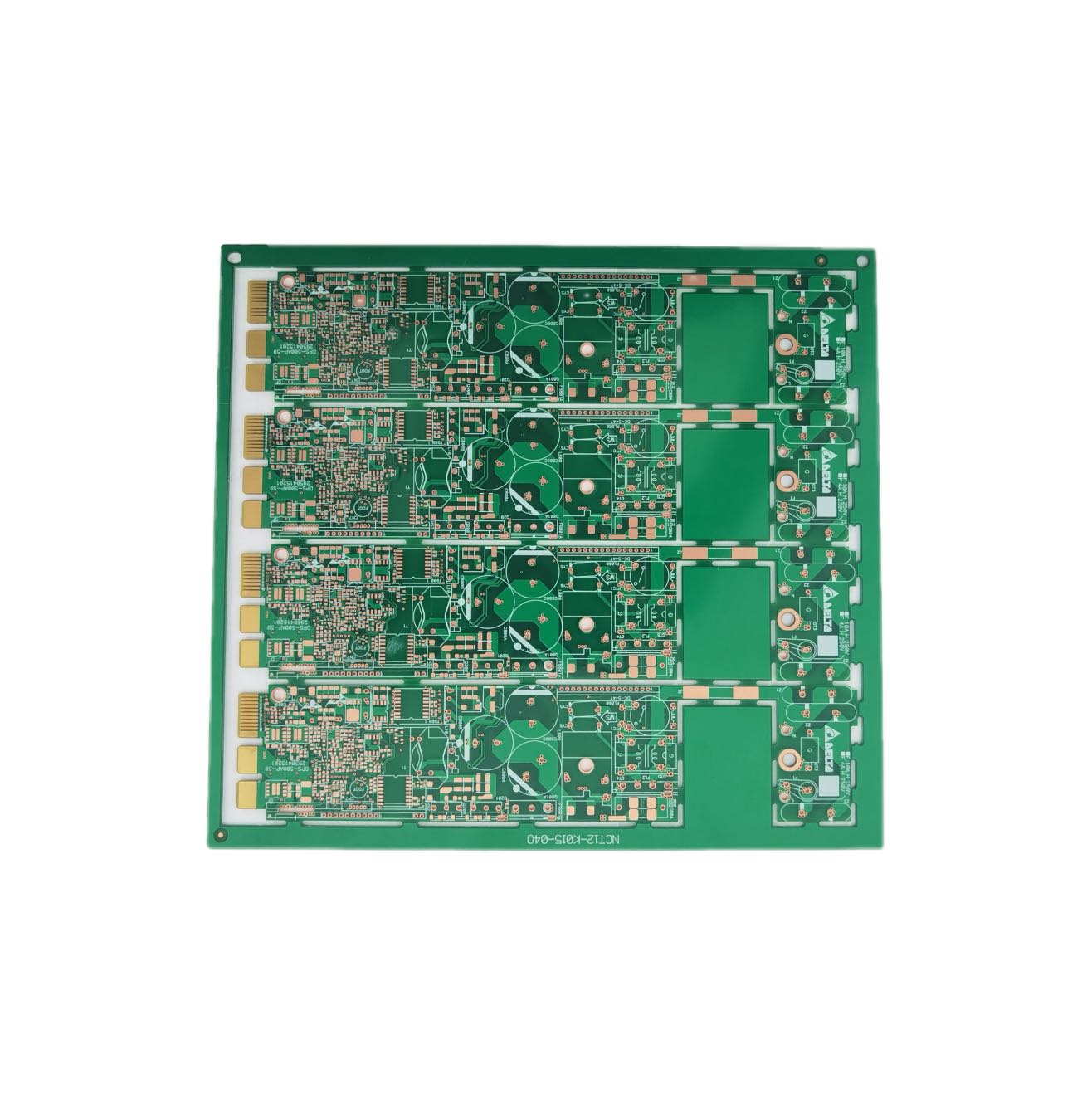

| High Density Interconnect(HDI) | 2+N+2 |

| Material type |

FR-4, High TG, Halogen Free, Rogers, ITEQ,ShengYi, Isola, Taconic, Arlon, Teflon, Rogers, Copper Based |

| Board thickness | 0.21mm to 7.0mm |

| Copper thickness | 0.5 OZ to 10 oz |

| Size | Max. Board Size: 580mm×1100mm |

| Min. Drilled Hole Size: 0.15 mm (6 mil)Min. Laser Drill 0.1mm(4mil) | |

| Min. Line Width: 3mil (0.075mm) | |

| Min. Line Spacing: 3mil (0.075mm) | |

| Surface finishing | HASL / HASL lead free,ENIG, Chemical Tin, Immersion Silver/Gold, OSP, Gold plating |

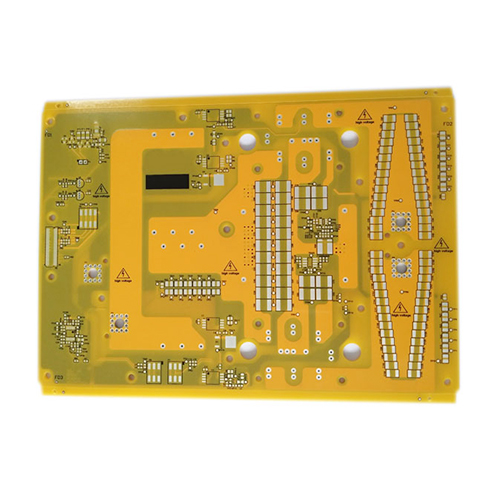

| Solder Mask Color | Green/Yellow/Black/White/Red/Blue |

| Tolerance | Shape tolerance: ±0.13(5mil) |

| Hole tolerance: PTH: ±0.075(3mil) NPTH: ±0.05(2mil) | |

| Certificate | UL, ISO 9001, ISO 14001 |

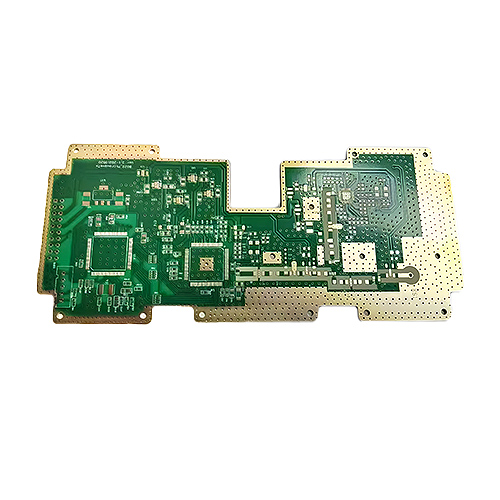

| Special requirements | Buried and blind via + Controlled impedance + BGA |

| Profiling | Punching, Routing, V-CUT, Beveling |

2.PCB Lead Time:

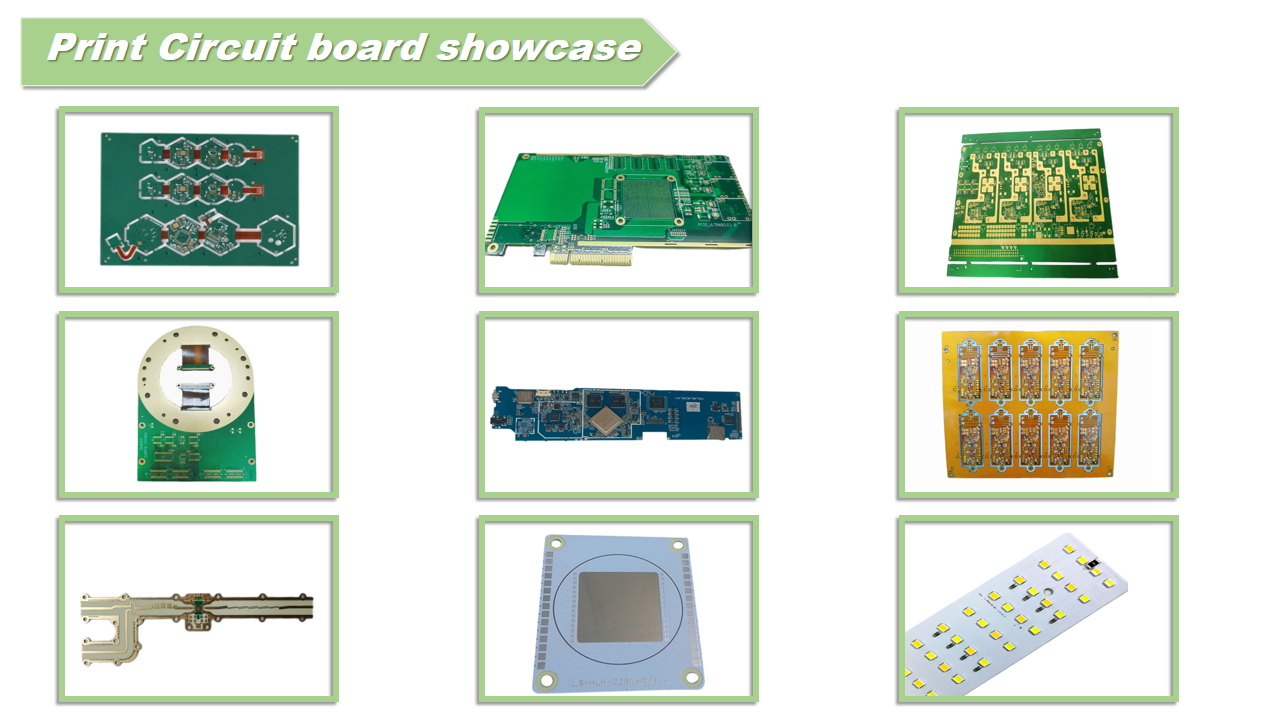

3.Products display

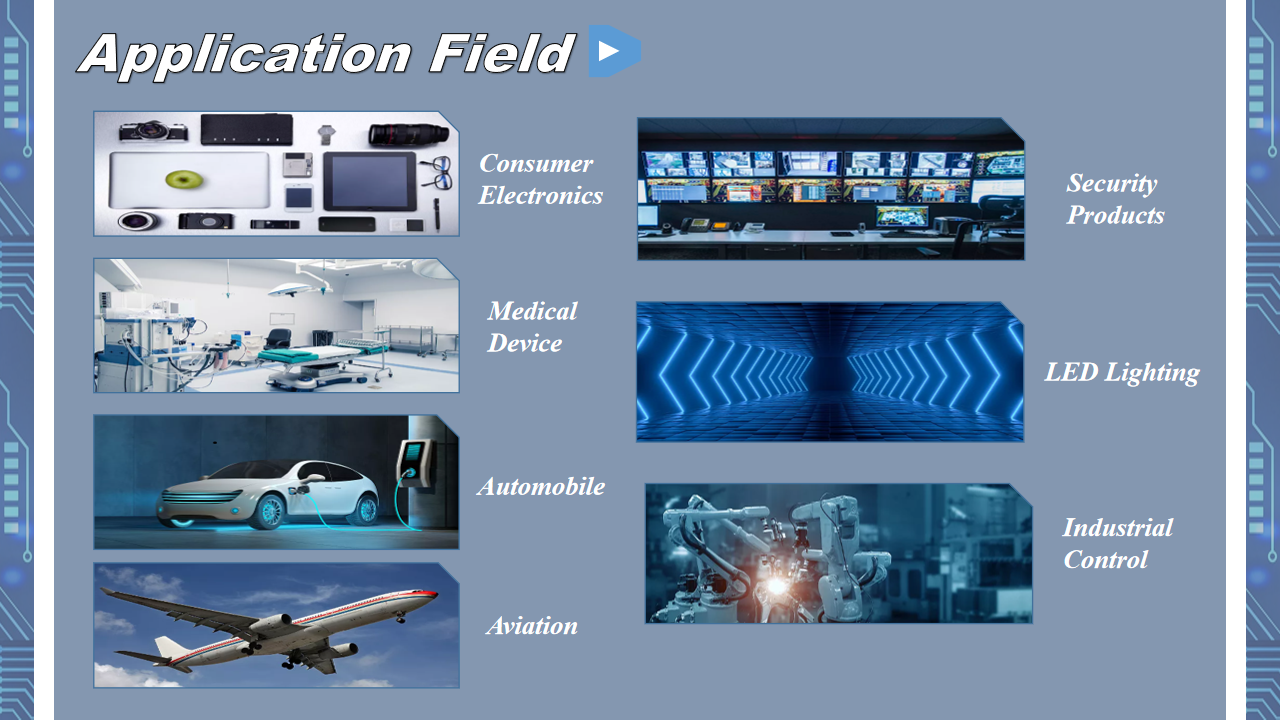

4.Products Application:

5.Factory Workshop:

Flame Resistance: 94v0

Product application: UAV

Main service: customization

TG Value: FR-4 TG170

Standard: IPC-A-610G CLASS II

Package:Vacuum Package

Related Products